The manufacture

leFoulard attaches great importance to high-quality, durable materials that are processed into silk and cashmere collections in a fair and environmentally friendly manner.

The silk

The silk is made from GOTS-certified natural fibres and spun in Italy in accordance with rigorous textile processing standards. Ecological requirements and social standards are maintained at the highest level throughout the entire production chain.

The cashmere wool

The wool comes from organic cashmere goats and is spun into fine yarn by Biagioli Modesto in Florence. The NM 2/48 cashmere yarn used is considered particularly fine and high-quality, giving the scarves their soft texture and durability.

Biagioli Modesto uses high-quality fibres for aesthetic reasons and as an expression of its commitment to producing sustainable and responsible products, and its deep respect for people and animals.

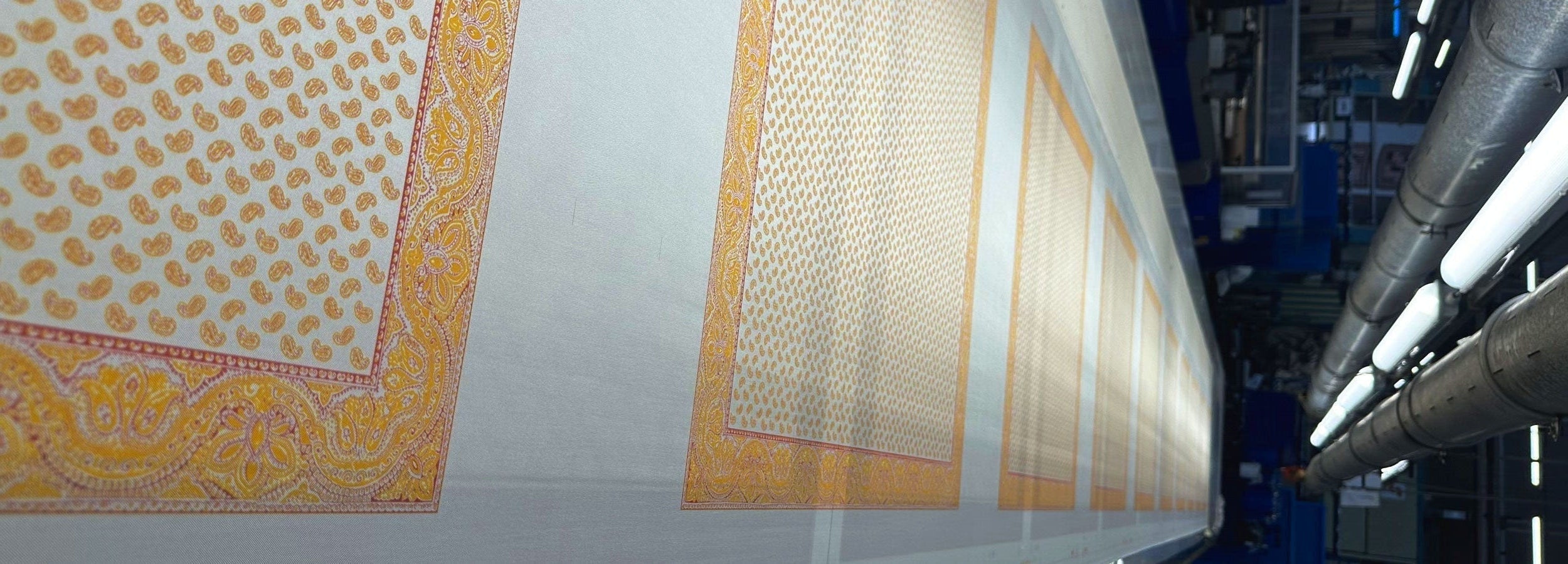

The printing process

From 2018 to 2023, all silk scarves were screen-printed at the last silk printing factory in Switzerland, located in Mitlödi. Since 2024, however, they have been printed by IsaSeta in Lombardy. The manufacturer is responsible for sourcing the raw materials and screen printing. They are committed to socially responsible, ecologically sound and resource-efficient production.

Compared to digital printing processes, traditional screen printing is very complex and involves many individual steps: the silk fabric is laid out on large flat film printing tables. Each individual printing ink is pulled over the respective pattern template using a squeegee. This tool distributes the ink evenly and then presses it through the fine-mesh fabric.

The “leGlaronais” collection requires four screen printing stencils, the “leDafi” collection requires two, and the “leBauhaus” collection requires a total of ten. Further insights into the production process can be found on the lefoulardcollection Instagram page.

Unlike the common digital printing process used today, screen printing guarantees a clear pattern on the front and back of the silk scarf.

The colors

IsaSeta only uses screen printing inks that are certified to Oeko-Tex® Standard 100, washable, skin-friendly and neither harmful nor allergenic.

Each new coat of dye is followed by a drying process. The dyes are washed and fixed in several washing cycles. This bonds the dyes permanently to the fabric, ensuring long-lasting durability and wash-resistant print results.

The knitting process

Each cashmere triangle is crafted by a traditional family business in Apolda, a town with a long-standing history of knitting.

The uniform structure and soft finish of the cashmere triangles are ensured by modern knitting machines operated by experienced knitters. Local production supports regional craftsmanship and eliminates the need for long transport routes.

The finishing

The silk scarves are finished with the utmost care. They are attached to a rolling stick and the hem is rolled up and sewn together by hand. This precise artisanal process ensures flawless workmanship and guarantees the longevity of the scarves.